COLLOID SQ-AMICROFINE CEMENT FOR SQUEEZE CEMENTING

Characteristics

COLLOID SQ-A is a one-component blast furnace slag-based ultrafine cementitious grout material.

It combines fast curing with rapid strength gain and high durability and is able to meet many grouting project needs.

It is used for water cut-off, ground reinforcement, and oil and gas squeeze cementing.

The production of NITTETSU COLLOID was ceased, and replaced by COLLOID SQ-A responding to the market requirement of faster set time.

Use

- 1. Water cut-off works of highly permeable rock foundations

- 2. Grouting of soil anchors

- 3. Grouting material used in tunnel construction, such as NATM

- 4. Grouting applications requiring quick hardening, high strength, and durability

- 5. Oil and gas well remediation

COLLOID CA(For Asia)MICROFINE CEMENT FOR SQUEEZE CEMENTING

Characterristics

COLLOID-CA is a blast furnace slag-based Microfine cementitious grout material with a D95 particle size of approximately 20 μm. It is able to permeate small cracks such as gaps and rock fissures, and improve strength and reduce permeability.

Use

- 1. Pre-and post-excavation grouting

- 2. Water cut cut-off grouting

- 3. Dam grout curtain

- 4. Soil consolidation

- 5. Stabilization of structure foundation

Construction Achievements

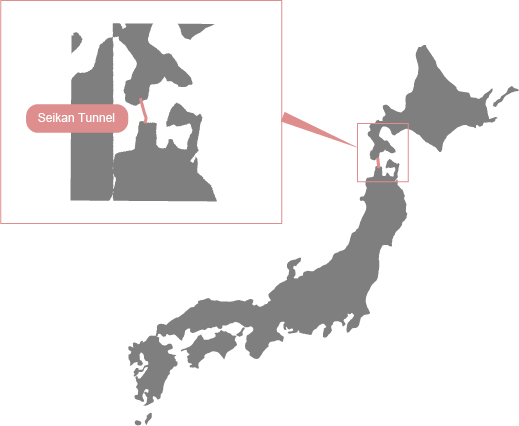

about The Seikan Tunnel

- Opened in 1988. The world's longest undersea tunnel.

- Product used: NITTETSU COLLOID

The Seikan Tunnel is an undersea railroad tunnel 53.85 km long (100 m and 240 m below the seabed) connecting Honshu and Hokkaido in Japan.

Mining construction was difficult due to water runoff. New leakage prevention measures were implemented, and new seawater-resistant spraying materials and Microfine Cement were developed for this construction.

After 27 years of construction, the tunnel was opened to traffic, and bullet trains and freight trains are still operating safely every day.

Inside the Seikan Tunnel

Inside the Seikan Tunnel

Location of Seikan Tunnel